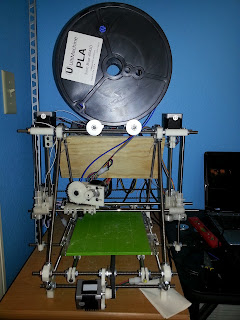

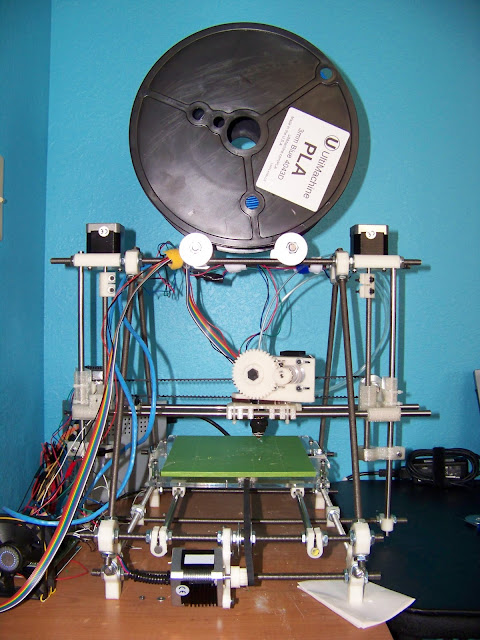

Upgrading The 3D Printer And Hexy Build Notes (Prusa RepRap)

What a busy couple of weeks I have had. Many upgrades for the printer have arrived, and work continues on understanding and possibly building Hexy before my Kickstarter version arrives from Arcbotics . In this post I will cover the upgrades I have made to the printer; why I made the upgrades, their cost; and finally show some updated Hexy prints to show off the new accuracy. First; I was printing the Seej Starter Set , in preparation for taking my printer to work on my last day. While doing so, the printer gave up the ghost. Badly. First, the z-axis was homing and went right down through the printer bed. So after a break and calming down, I put the z-axis back together, calibrated; and went to home it again. Same thing, it went right down through the printer bed; which was saved by being spring loaded. This time though; the z-axis couple snapped in half. So, because of this complete printer failure and needing to order new parts anyway; I decided to do the upgrades that are sugges...